Handloading the 50-70 for Antique and Modern Rifles

Handloading the 50-70 for Antique and Modern Rifles

by Croft Barker

Most single shot aficionados are aware of the fact that the fifty-seventy Government cartridge was first issued to U.S. Army units in 1866 for use in the Model 1866 Springfield trapdoor. This rifle was our first standard issue military centerfire longarm and, as such, was much used in the post-Civil War expansion of our western frontiers.

For the last fifty years or so both the written and spoken word have relegated this venerable warrior to plinking and the taking of big game at 125 yards or nearer. Many uninformed writers have called the 50-70 the “big fifty” (a title reserved for the 50-90 Sharps). Several scribes have claimed that the old government cartridge is not accurate enough for match shooting. I disagree. I suspect that most of these scribes fired the 50-70 little or not at all. Repeating old wives tales and second hand stories is not a substitute for accurate information and gives rise to a plethora of misinformation.

Accuracy. Before getting into the subject of handloading we should first define “accuracy” as it applies to the fifty-seventy. Based upon personal experiences of shooting this round for thirty-five years, I would say that a modern match rifle is capable of shooting 1 to 1 minute groups with Vernier peep rear sight and spirit level aperture front sight mounted. This group size has been confirmed by hours of shooting paper targets at 100, 200, 300, 400, and 600 yards. My match rifle sports an original Remington No. 1 rolling block action, single set trigger and a 34″ Badger barrel (trigger job and re-barreling by Dave Higginbotham of Lone Star Rifle). The sights are Parts Unknown [now Red River Sights] rear and Pedersoli front. Wood is by Treebone Carving hand fitted by me. One proof in the accuracy pudding is that this rifle allowed me to reach Master Class in BPCR Silhouette. In 2003 it fired a 5 round 2-1/2″ group at 200 yards on a paper target (as measured by Mr. Dick Trenk of Pedersoli) in a side match at the Coors Range in the Whittington Center near Raton, New Mexico. Upon measuring, Dick was very surprised that a 50-70 could shoot a 1 MOA group.

Photo below shows, L to R, match round loaded with un-sized case, custom 50-70 neck sizing die, neck sized round for military rifle.

Antique military rifles (in good condition) with issue sights generally shoot 1 to 3 MOA groups depending on the eyes of the shooter. Because my eyes are over sixty years old, open sight groups are not as good as they once were. When shooting my match rifle, scores have not changed because I can adjust the Hadley eyecup to the correct aperture allowing me to see the front sight and target well enough. The 1 to 2 MOA military rifle groups were fired with my M-1866, M1870 trapdoors and M-1870 Navy rolling block. My M-1868 Sharps carbine shoots slightly larger groups due to a shorter sight radius and an extremely heavy trigger. In order to shoot tight groups, each of these military rifles were tuned by me. Most antique and many modern rifles require tuning to realize top performance. Tuning for accuracy is beyond the scope of this article but the methods used are described in Restoring and Shooting the Antique Single Shot Rifle and The 50-70 Shooter’s Handbook both available from Cistern Publishing.

Antique military rifles (in good condition) with issue sights generally shoot 1 to 3 MOA groups depending on the eyes of the shooter. Because my eyes are over sixty years old, open sight groups are not as good as they once were. When shooting my match rifle, scores have not changed because I can adjust the Hadley eyecup to the correct aperture allowing me to see the front sight and target well enough. The 1 to 2 MOA military rifle groups were fired with my M-1866, M1870 trapdoors and M-1870 Navy rolling block. My M-1868 Sharps carbine shoots slightly larger groups due to a shorter sight radius and an extremely heavy trigger. In order to shoot tight groups, each of these military rifles were tuned by me. Most antique and many modern rifles require tuning to realize top performance. Tuning for accuracy is beyond the scope of this article but the methods used are described in Restoring and Shooting the Antique Single Shot Rifle and The 50-70 Shooter’s Handbook both available from Cistern Publishing.

Components and Equipment. There are considerable variances in bullet diameters, chamber dimensions and twists between antique and modern 50-70 rifles. Because of these differences, the old and new versions will be treated as two distinct cartridges.

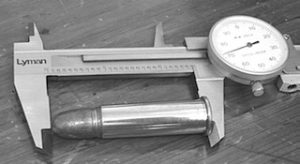

Bullets. Before shooting any antique, the bore must first be slugged and groove  determined after removing all crud and leading from the barrel. Many old rifles contain heavy lead deposits immediately in front of the chamber. This leading is usually the result of firing grossly under-diameter bullets. Photo at right: measuring uncompressed powder column height with under-diameter bullet.

determined after removing all crud and leading from the barrel. Many old rifles contain heavy lead deposits immediately in front of the chamber. This leading is usually the result of firing grossly under-diameter bullets. Photo at right: measuring uncompressed powder column height with under-diameter bullet.

Groove diameters in original military 50-70s range from about .515″ to .518″. A year ago a friend, Gene Reynolds, sent me a lead slug he had driven from muzzle to breech through the barrel of a Second Allin Conversion (Model 1866 trapdoor). It miked out at .505″ groove diameter.

Gene had just finished reading The 50-70 Shooter’s Handbook and wanted to know why the slug was .010″ to .011″ under the diameter I indicated therein. The slug he sent exhibited only two lands and grooves (the M-1866 has three). I called Gene and asked how many grooves he could see. He said there were three at the muzzle but only two in front of the chamber of his newly acquired toy. After a major de-leading operation, Gene re-slugged the barrel and determined correct groove diameter was .516″. Obviously there was a heap of lead in the chamber end of this barrel.

Why would the prior owner (or anybody else) fire an under-diameter bullet with low accuracy and high leading potential? The answer is that current production 50-70 rifle barrels (Badger for example) are cut with groove diameters of about .512″. The majority of late 20th and early 21st century moulds (the Lyman 515141 for instance) cast bullets designed for modern rifles. These bullets drop from the mould at around .510″ to .512″ diameter. Shooting a .004″ to .007″ under-diameter bullet in your pet 50-70 will result in a beaten area in lieu of a tight group and will provide an opportunity to try out all of your favorite lead removal fluids and gizmos. The next question is: what is the correct bullet diameter for a .516″ groove diameter barrel?

It depends. If the charge is black powder and bullet alloy is 1:30 tin/lead or softer then I would select a bullet of groove diameter or .001″ to .002″ smaller. Although black powder “bumps” bullets up more than smokeless, I would not shoot any bullet (except a Minie or paper patched) that was more than .002″ under groove diameter. When firing smokeless rounds I would choose a bullet of .001″ over groove diameter to prevent leading and enhance accuracy. The above (with Minie and paper patched exceptions noted) applies to naked lead or soft alloy lubricated bullets. If the bore is deeply pitted, firing a .004″ to .006″ under-diameter bullet that is then paper patched will result in zero leading.

Where do we find production moulds that cast correct diameter (and length) bullets for both antique and modern barrels? For antique rifles with 1:42 twists (M-1866, M-1868, M-1870 trapdoors and M-1870 Navy, M-1871 Army, N.Y. State Militia rolling blocks, etc.) the Lee #90255 is an excellent choice. The bullet is .990″ long with an as-cast diameter of .518″ and weighs 447 gr. when cast from 1:30 alloy. This bullet is then sized to the correct diameter and lubricated with SPG or similar. Please note that any bullet over an inch long will wobble in flight and print oval (instead of circular) holes in your target when fired from a 1:42 twist. The Lee #90255  has proven itself in 1:42 to 1:30 twists with .515″ to .516″ groove diameters.

has proven itself in 1:42 to 1:30 twists with .515″ to .516″ groove diameters.

Photo at right: 50-70s: M-1866 trapdoor, M-1870 Navy R.B., M-1868 Sharps, modern match rifle.

For modern rifles with .510″ to .512″ grooves the Lyman #515141 mould drops bullets of

slightly under and inch in length with diameters of .511″ to .512″. The Lyman #515142 casts bullets of the same diameter with a length of 1.05 inch that weigh 520 gr. in 1:30 alloy. When fired in 1:26 twist or quicker twist barrels, a bullet of up to an inch and a quarter long (to my certain knowledge) is stable in flight. My match bullet for 300 to 750 meter shooting drops from NEI’s mould #512600 at .512″ diameter and is sized to .511″. This bullet is a round nose with a long, sweeping ogive and resembles a pregnant Postell. It is 1.26″ long and weights 598 grains when cast from 1:30. This bullet is extremely accurate when fired from a 1:26 twist but when fired from a 1:42 twist it enters the target sideways (keyholes) at 100 yards. The 598 gr. bullet has an amazing effect on the 300 meter pigs. They spin, hum and fairly leap from the rail when hit. Spotters complain that they can’t see bullet splatters on the javalinas due to their rapid flight when zapped by this heavy projectile.

Wads. Are used when firing cartridges stoked with black powder and are available from John Walters and others. Regardless of wad thickness or material, (.030″, .060″, etc.) two newsprint wads placed between the primary wad and the base of the bullet are highly recommended to prevent the primary wad from sticking to the base of the large diameter bullet. The newsprint wads are added after the primary wad is compressed with the charge.

Brass. May be formed from .348 Winchester (though the rims are a bit under-diameter) or purchased from Starline Brass. BELL cases may still turn up although the company is out of business. Dixie Gunworks is yet another source. I happen to have some unfired Bell brass (it is not for sale) and decided to compare it to my Starline (ordered from Buffalo Arms). Of six examples compared from each manufacturer, the Bell averaged 205.8 grains with a range of 203.0 to 211.6 gr. The Starline averaged 214.1 grains ranging from 213.0 to 215.4 gr. Maintaining consistent case volume is a boon for the black powder reloader as it results in more consistent compression.

Primers. After dinking around with several different makes and trying standard, magnum and match types, I have decided that Winchester Large Rifle Magnums are best for all of my 50-70 BP loads. These are very hot primers that promote fast ignition and lessen fouling.

Powder. The color is black. Although I have loaded smokeless in 50-70s for years, I’ve come to the conclusion that black powder is more accurate and safer than smokeless (you can’t double charge a black powder load). GOEX 2F generates plenty of energy, is accurate and much less expensive than the European imports. It performs best in my rifles when drop tubed then compressed .090″.

Reloading dies. For modern rifles standard three piece die sets as manufactured by Lyman, RCBS, et cetera will serve. These are designed for .512″ diameter bullets. Compression dies are available from Buffalo Arms and the same one may be used on either modern or antique dimension black powder loads.

Cases for antique rifle loads utilizing .515/.516″ bullets may be full length sized with standard dies but the cases will be a sloppy fit in the old over-sized chambers. When neck sizing cases with a standard FL die, the case area below the neck will also be partially sized. An issue with modern expander dies is that the expander plug is too small for .515/516″ diameter bullets. My Lyman “M” plug measures .510″ in diameter while my RCBS is .507″. Custom (correct) diameter expander plugs for Lyman, RCBS and other dies are available from Buffalo Arms. The big problem with standard dies is that they over-size cases destined for antique chambers.

The other problem is inside neck diameter. The inside neck diameter of fired cases from my match rifle is .512″. This provides a perfect slip fit for .511″ diameter match bullets. These cases are never sized once fire formed. Inside neck diameter of my fired M-1866 cases is a cavernous .521/.522″. This is way too large for my .515″ diameter bullets. What was needed was a 50/70 neck sizing die (a non-standard item) that would size the case neck without sizing the bullet or lower part of the case.

I contacted two major die manufacturers for price and delivery. Both quoted approximately three months. I then ordered a 50-70 neck sizing die from Harold Parks (a gunsmith/ machinist) of Sunrise Pass Arms Co. and received same in two weeks. Harold’s dies are not tempered and are about as hard as a carbon steel rifle barrel. This has not presented any problem with either the 50-70 neck die nor a full length sizing die he made for my .58 Berdan caliber rolling block. The new neck die is tapered so that anything from a slip fit to a tight one can be accommodated. I am very pleased with this die. Harold’s phone number is (775) 267-2284.

If you have been reading between the lines, you may have noted that I am not an advocate of full length resizing cases fired in antique chambers. In the first place, the dimensions of modern FL sized brass are grossly undersized for antique 50-70 chambers and must be fire formed for a correct fit. This equates to fire forming a modern wildcat case from a standard one. Once the wildcat is fire formed why would we want to return it to the parent case dimensions? If we FL size with modern dies then we are sizing our brass to the dimensions of the parent (modern 50-70) case. Another consideration is accuracy. When FL sized cases lie in the bottom of the chamber with daylight showing at the top then the bullet will not be aligned with the bore. The last point is case longevity. When paying at least $1.32 per case I want mine to last as long as possible. Full length resizing is not conducive to extended case life.

Miscellaneous Gear. Standard size deburring tools are too small for .50 calibers and can damage the neck O.D. What is needed is the Lyman Deburring Tool, Item #7810206. When firing BP rounds, I always deprime my cases at the range then drop them into a jug of soapy water. The “de-capper” used is quick, efficient, made for any caliber and is relatively inexpensive. The maker of this highly recommended item is Jimmy Hagar (918) 342-3465.

Handloading Procedures. First ensure that each case will chamber, if any case will not chamber then resize the entire lot. Determine maximum overall cartridge length with the bullet you will be shooting. When firing black powder, overall length should be at least .005″ shorter than maximum length to allow easy chambering in fouled barrels.

Case preparation. The flash hole is reamed with the Lyman tool and the case mouth deburred. The neck is then expanded and belled (if required). The case is not length trimmed until it has been fired at least five times. The case will not (due to low chamber pressures and thick walls) fully fire form until it has been fired several times. Trimming before fire forming will result in too-short cases.

Priming. Is done with a RCBS hand priming tool (or similar) that accepts a standard shell holder. Some priming tools with proprietary shell holders will not accept the large 50-70 base or rim.

Charging with black powder. A weighed charge is drop tubed into the case. The uncompressed powder column is then measured with an undersized bullet that slips freely into the case. Ten charges are drop tubed and the average height calculated. All uncompressed column heights should not vary more than .002″ over or under the average height. If not over .010″ too high, the case (with undersized bullet in place) is tapped until correct height is achieved. If over .010″ too high then the charge is drop tubed more slowly. If the column is too short then the charge is dropped faster. Without consistent uncompressed powder column height, consistent compression is impossible. Without consistent compression, vertical stringing instead of circular groups will result. This is particularly true of loads featuring little or no neck tension.

The primary wad is now inserted and the compression die adjusted to compress the charge .090″ (when using Goex 2F). Different powder/rifle combinations require different compression, however, .090″ is a good starting point with 70 grains of Goex 2F. Two newsprint wads are now installed and the lubricated bullet is seated by hand or with the bullet seating die. Because I use fire formed brass, I seat the bullet by hand. The loaded cartridge is then run into the neck sizing die. The die is then adjusted to give the desired neck tension. I like a snug slip fit as the bullet is not sized and the brass is little worked. If the case has already been sized then the expander die is used and the bullet seated with the seating die. When using the seating die, particular care must be exercised to ensure that the base of the bullet is not above the wad nor compressing the charge (the former will result in vertical strings and the latter may result in chambering difficulties due to the bullet having been bumped up). Remember that we are using soft alloy or pure lead bullets that are easily deformed.

Accuracy Tips. Begin reloading with clean brass. Cruddy neck I.D.s will result in inconsistent neck tension. Deprime brass immediately after firing and dump into a jug of soapy water. Upon returning home, rinse in clean water and toss (while still wet) into a walnut media filled tumbler and leave for six to eight hours with the top off (to allow the cases to dry).

Experiment with overall cartridge length. I generally seat the bullet out to expose one grease groove with the driving band resting on the case mouth. This step allows the bullet to be better aligned in the chamber while being centered in the case.

When switching from one lot of powder to another (of the same brand and granulation) you may find that the uncompressed powder column will be higher or lower than the previous lot. If this happens, adjust charge weight in order to maintain the previous uncompressed column height. In this way compression will remain the same as before. When changing from one brand or granulation to another, the amount of compression will have to be re-figured. For some reason the 50-70 fouls more than my 45-70, 11.15 x 58Rs, 38-55, etc. To avoid vertical strings, two additional puffs on the blow tube are required.

Conclusion. Compared to other straight case black powder cartridges, the 50-70 Government is no harder or easier to handload. Most accuracy problems seem to stem from firing under-diameter or over-length bullets in antiques followed by inconsistent compression and poor fouling control. I shot vertical strings from my match rifle (with each shot printing lower than the last) for nearly a year before it dawned on me that five to eight puffs on the blow tube were better than one. With proper reloading and shooting techniques our most historic centerfire is still a winner.~

Guy Haines

Any advice for the process of forming 348 Win to 50-70? Any concerns with the differences of dimensions, primarily the under diameter rim? Thanks

Corrie Willis

When I stretch a case that far I am always careful to keep the case neck annealed and soft as I work along, and stretch the neck and body in small increments. I have never done the conversion you mention but I would guess it might need annealed a couple of times as you stretch it that far.

The undersized rim will only be a problem if your extractor is worn or not fitted well.

Hope that helps,

Lee

Guy Haines

Thank you Lee. Good points. Yeah, the 50-70 brass is nowhere to be found, but 348 win seems to be fairly easy to find for the moment. I have also considered fireforming, but I am still new at all this. Thanks again.

Gerald E Mahle

Bayou Brass, Mandeville La. has .50-70 Starline brass. Comes in 25-round lots at a reasonable price (around $1.30 ea.) any quantity. Starline always has a good reputation. I purchased some two weeks ago. Beautiful brass.

Anthony J Perille

I have a Billy Dixon Pedersoli sharps in 50-70 I load 71 gr. olde eynsford 2f cci 250 large magnum primers 1 milk wad compression .118 lube ribbon 2 paper wads with a 600 gr. Paper patch bullet, 1206 fps. At 100yds with barrel sights off cross sticks grope 2 3/4″ in the ten ring.

Matt white

Can anyone recommend a trimmer that works to take my cut .50 basic cases case to .50-70?(1.75 inch). I can get close with my tube cutter but can’t find a trimmer that trims .50-70. thank you!

David Miller

I use a C-H trimmer, which is a lot like a L.E. Wilson. I used a WSM case holder and reamed it with a 50-70 chamber reamer. this is a trial and error operation. You only want to ream it until the SIZED case fits tightly. You may also need to shorten the holder. (can’t remember)

I use a 50 caliber cutter from L.E. Wilson. You will also need to ream the part of the trimmer that holds the cutter. Now I just use the 50 caliber cutter for trimming all calibers.

Corey Wood

Got any advice on what pressure an 1866 2nd Allin can handle? i want to load mine with smokeless, but i want to be safe about it. The barrel is from an 1863 Springfield and is in great shape. Please let me know. Thank you!

Corrie Willis

A good quality 1866 Allen conversion rifle will handle black powder pressures just like any other good trapdoor rifle. There is not much in the way of published smokeless loads for the .50-70, but it can certainly be used.

Loaddata.com lists no less than 20 different smokeless loads for the .50-70, but you must be a subscriber to their website to be able to see the load data. Even they say the loads should be used only in rifles that are safe for smokeless powder.

Hope that helps,

Lee Shaver, Publisher

japanese watercolor landscape

Because of the large floor space of these rounds, they lose velocity rapidly, and must be used at pretty short ranges to

be effective, though use at extremely brief ranges, beneath three

m (9.Eight ft), can lead to damaged bones or other severe or lethal injuries.